Dryers

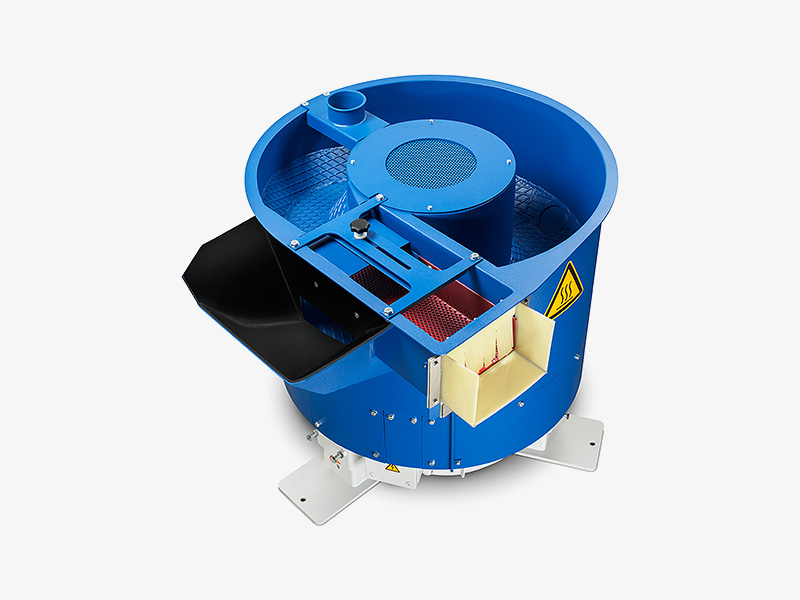

G-series Vibration Dryer

PROTECTING YOUR SENSITIVE PARTS

The bowl channel pitch is helically shaped and has no ramp, making the G dryer especially gentle when handling your workpieces. The high heating power is fully adjustable. The heater with replaceable heating elements is assembled separately from the vibrating section. To ensure your working environment is protected from dust, the dryer can also be fitted with a dust extractor.

EASY INTEGRATION INTO THE MASS FINISHING PROCESS

A rubberised feed hopper for your workpieces is located on the side of the unit, so that you can effortlessly link the dryer with the upstream mass finishing machine. The pneumatically operated screening unit also makes incorporation into a full processing system easier, regardless of whether you are using batch or continuous operation.

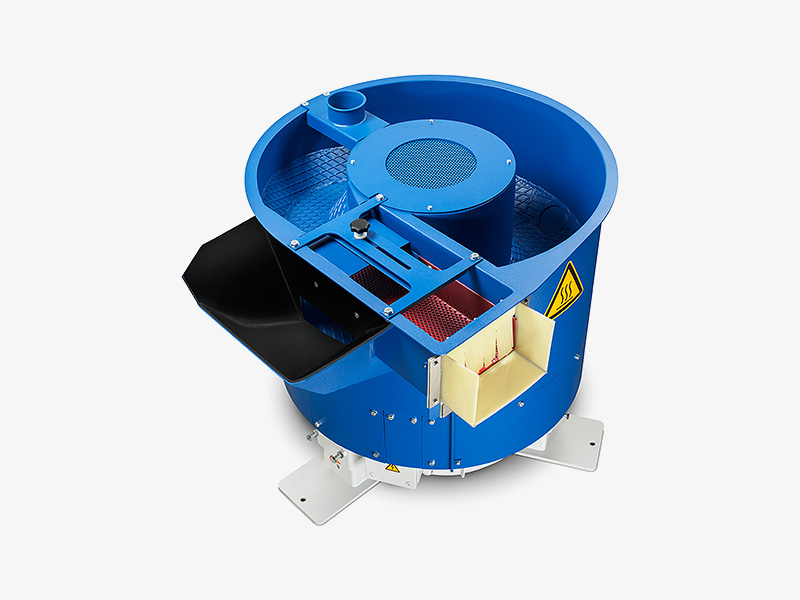

PROTECTING YOUR SENSITIVE PARTS

The bowl channel pitch is helically shaped and has no ramp, making the G dryer especially gentle when handling your workpieces. The high heating power is fully adjustable. The heater with replaceable heating elements is assembled separately from the vibrating section. To ensure your working environment is protected from dust, the dryer can also be fitted with a dust extractor.

EASY INTEGRATION INTO THE MASS FINISHING PROCESS

A rubberised feed hopper for your workpieces is located on the side of the unit, so that you can effortlessly link the dryer with the upstream mass finishing machine. The pneumatically operated screening unit also makes incorporation into a full processing system easier, regardless of whether you are using batch or continuous operation.

The Benefits At A Glance

Key Features and Advantages for Optimal Performance and Versatility

- Additional polishing of your workpieces

- Helically shaped bowl channel pitch with no ramp

- Side-mounted rubberised workpiece feed hopper

- Fully adjustable heater with replaceable heating elements

- Integrated screening unit for batch and continuous operation

- Polyurethane container cladding (optional)

- Dust cover with integrated dust extractor and filter unit (optional)