Drag Finishers

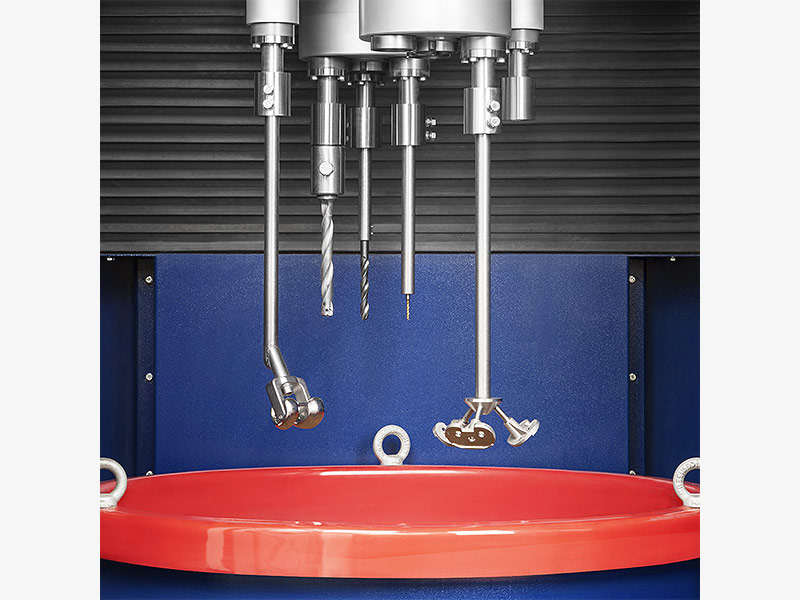

M-TMD Drag Finisher

A HIGHLY EFFICIENT METHOD WITHOUT THE RISK OF WORK PIECES DAMAGING EACH OTHER

Compared to standard mass finishing systems the newly developed M-TMD machine range finish high-value components 10 to 20 times more efficiently! By mounting the work pieces individually to workstations, which are part of a rotating carousel, you can process up to 18 work pieces in one single batch without risking part-on-part impingement.

Different workstation angles – relative to their vertical position – allow the individual adaption of the machine parameters to your work pieces and guarantee absolutely stable finishing processes with excellent and repeatable results.

Applications

Key Features and Advantages for Optimal Performance and Versatility

- Orthopedic implants (medical engineering)

- Turbine blades (for airplanes as well stationary turbines)

- Precision components, for example, for pumps and compressors

- Work pieces made from tungsten carbide and other hard metals

- Fan wheels for turbo chargers (automotive industry)

- Sintered components, etc.